Top 5 Benefits of Plastic Injection Molds for Your Business?

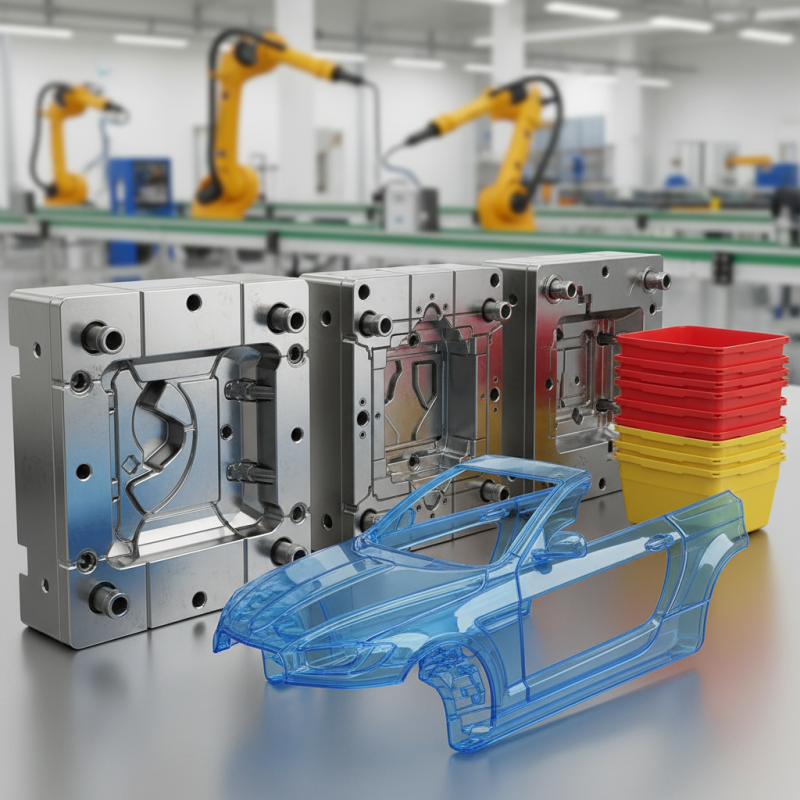

In today's competitive market, businesses seek efficient manufacturing solutions. One method that stands out is the use of Plastic Injection Molds. These molds are crucial in producing high-quality plastic products for various industries.

Plastic Injection Mold technology enables companies to create complex parts with precision. This process saves time and reduces waste, leading to cost-effective production. Many businesses have adopted this method to enhance their product lines. However, it's essential to choose the right mold design. A poorly designed mold can lead to defects and increased costs.

Moreover, while Plastic Injection Molds offer many benefits, they also require careful planning. Companies should consider their specific needs before investing. Understanding the limitations and potential challenges of this technology is vital for long-term success. Balancing innovation with practicality can sometimes be challenging, yet it is crucial for sustainable growth.

Advantages of Using Plastic Injection Molds for Manufacturing

Plastic injection molding has become a vital manufacturing process. It offers several advantages that can significantly impact a business's success. One of the key benefits is efficiency. According to a study by the Society of Plastics Engineers, injection molding can produce parts at a rate of up to 400 units per hour. This rapid production allows businesses to meet high demand swiftly.

Cost savings is another notable advantage. Research from the American Injection Molding Institute highlights that plastic injection molds can reduce production costs by up to 30% compared to traditional methods. The materials used are often less expensive, and less scrap is generated during the process. However, the initial setup for molds can be costly, and this investment needs careful consideration.

Consistency in quality is crucial for many manufacturers. Injection molding ensures uniformity in mass production, as each piece is molded under the same conditions. This reduces the variability that can occur with other manufacturing techniques. Yet, achieving perfect consistency can be challenging. Small variations in temperature or pressure can lead to defects, which require ongoing quality control efforts. Attention to detail is essential in this process.

Cost-Efficient Production and Material Usage with Injection Molding

Injection molding is a game-changer for businesses focused on cost-efficient production. This method uses less material than traditional processes. With precise designs, it minimizes waste. Only the necessary amount of plastic is used. Companies can save significantly on raw material costs. This efficiency translates into lower unit prices, boosting profit margins.

Moreover, injection molding supports high-volume production. Once the mold is created, it can produce thousands of identical parts. This consistency reduces the time and money spent on quality control. However, the initial investment in molds can be daunting. Not all companies are ready for this. It requires careful planning and assessment of future needs.

Another aspect to consider is the flexibility of design. Injection molds can adapt to different shapes and sizes. Yet, changing the mold can be costly and time-consuming. Businesses must weigh the pros and cons before diving in. The benefits are clear, but so are the challenges. Planning and strategy are crucial for successful implementation.

Enhancing Product Quality and Consistency through Molding Techniques

Plastic injection molding is a game changer for many businesses. It enhances product quality and consistency. According to industry reports, precision manufacturing through injection molding reaches 95% accuracy. This eliminates variations often seen in traditional methods. A consistent output fosters brand reliability.

Molding techniques allow for intricate designs with minimal defects. For example, the use of multi-cavity molds can increase production speed and reduce unit costs. Research indicates that companies can cut production time by up to 30%. However, achieving these results requires investment in high-quality molds and processes. Lower-quality molds can lead to costly rework and delays.

Despite these advantages, some businesses still struggle with mold maintenance and optimization. It's essential to regularly inspect molds and ensure proper cleaning. Neglect can result in decreased performance and inconsistencies. The key is to balance quality control with efficiency. For many, the road to effective injection molding may be fraught with challenges, but the potential rewards can drive substantial growth.

Faster Production Times: The Efficiency of Injection Molding Processes

Injection molding is a cutting-edge process that greatly enhances production efficiency. With this method, businesses can create high-quality plastic parts in rapid succession. The speed of this process often leads to shorter lead times. This means products can reach the market much faster than traditional methods allow. As a result, companies can respond swiftly to customer demands.

One essential tip for optimizing production times is to focus on mold design. A well-designed mold can reduce cycle times significantly. Evaluate your designs regularly. Are they maximizing efficiency? Small adjustments can lead to improvements.

Another point to consider is material choice. Some plastics perform better in injection molding processes than others. This affects both speed and quality. Research various materials and their properties carefully. Choose the one that aligns with your production needs. Remember, finding the right balance can be a trial-and-error process. It requires ongoing assessment and adaptation to make it work effectively.

Top 5 Benefits of Plastic Injection Molds for Your Business

| Benefit | Description | Impact on Production |

|---|---|---|

| Faster Production Times | Injection molding allows for rapid production with high efficiency. | Increased output in shorter timeframes. |

| Cost Efficiency | Initial setup costs are offset by higher production volumes. | Lower cost per unit as production scales. |

| High Precision | Produces parts with tight tolerances and minimal variability. | Enhanced product quality and reduced waste. |

| Design Flexibility | Allows for complex shapes and designs that are difficult to achieve with other methods. | Opportunity for innovative product development. |

| Material Versatility | Supports a wide range of thermoplastics and blends. | Ability to cater to diverse customer needs and applications. |

Design Flexibility and Innovation Opportunities with Custom Molds

Custom plastic injection molds offer remarkable design flexibility. Businesses can create unique shapes and sizes tailored to their specific needs. This adaptability opens the door to innovative product designs that can capture consumer interest. Imagine a product that combines functionality and aesthetic appeal, tailored precisely to market demands. Custom molds make this possible.

The beauty of these molds lies in their ability to accommodate complex geometries. New ideas can flourish without the constraints typically found in mass production. However, adopting this approach does have challenges. Initial costs may be higher, and lead times can vary. Companies need to evaluate whether the investment is worth the potential returns.

Moreover, the process requires constant feedback and iteration. Businesses must remain open to refining designs after testing prototypes. Mistakes can lead to extra expenses and delays, highlighting the importance of thorough planning. The road to innovation can be bumpy, but the rewards often justify the effort. Embracing this flexibility can ultimately lead to groundbreaking products that stand out in a competitive market.