Exploring the Advantages of Best Vacuum Equipment for Maximizing Industrial Efficiency

In today's fast-paced industrial landscape, the quest for efficiency drives businesses to adopt innovative technologies that optimize operations. Among these advancements, vacuum equipment stands out as a vital asset in enhancing productivity across various sectors. This blog delves into the advantages of utilizing the best vacuum equipment available, highlighting how it can significantly streamline processes, reduce costs, and improve overall outcomes.

By comparing different vacuum systems, we aim to provide insights into their unique benefits, helping businesses make informed decisions that align with their efficiency goals. Whether for material handling, packaging, or other industrial applications, understanding the capabilities of diverse vacuum equipment can pave the way for operational excellence and sustained growth in competitive markets.

Benefits of High-Quality Vacuum Equipment in Industrial Settings

High-quality vacuum equipment plays a crucial role in enhancing industrial efficiency across various sectors. By ensuring effective material handling, optimal process control, and improved product quality, these tools significantly contribute to the smooth operation of industrial processes. Industries such as packaging, food processing, and pharmaceuticals particularly benefit from utilizing advanced vacuum technology, as it minimizes contamination risks and boosts production speed.

Tip: Conduct a thorough assessment of your production line to determine the ideal vacuum solutions that fit your workflow and material characteristics. Additionally, investing in equipment with reliable performance can lead to reduced downtime and maintenance costs, ultimately enhancing productivity.

Furthermore, integrating high-quality vacuum equipment can lead to energy efficiency, as many modern systems are designed to consume less power while delivering superior performance. Tip: Look for vacuum systems that feature energy-saving technologies or controls, which allow you to optimize energy consumption based on operational demands. These strategic improvements not only help your bottom line but also contribute to a more sustainable industrial environment.

Understanding How Vacuum Technology Enhances Production Efficiency

Vacuum technology plays a crucial role in enhancing production efficiency across various industrial sectors. By creating a controlled environment free of contaminants, vacuum equipment minimizes defects in products, which ultimately leads to a more streamlined manufacturing process. According to a report from the International Vacuum Society, industries adopting advanced vacuum systems have seen a 25% increase in production rates while reducing material waste by up to 30%. This efficient utilization of resources not only lowers costs but also boosts overall productivity.

To maximize the benefits of vacuum technology, consider these tips:

Invest in high-quality vacuum pumps that are specifically designed for your production needs. Regular maintenance of your vacuum systems is vital; it can prevent downtime and costly repairs. Additionally, training your workforce on the best practices of operating vacuum equipment can lead to improved safety and efficiency. Implementing these strategies will ensure that your industrial processes leverage the full potential of vacuum technology for optimal productivity.

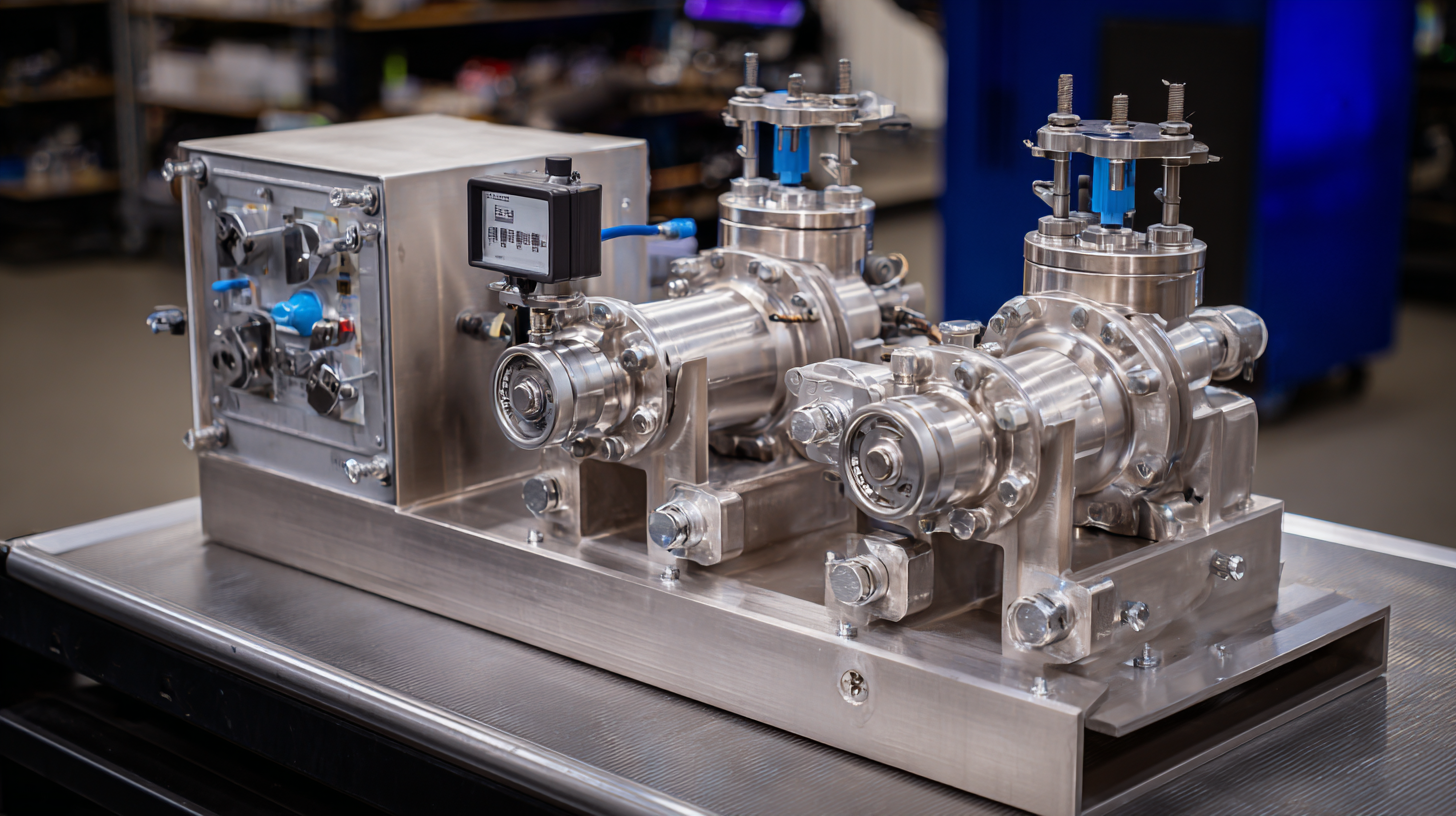

Key Features to Look For in Industrial Vacuum Systems

When selecting the best vacuum equipment to enhance industrial efficiency, it's essential to focus on specific key features that can influence performance and productivity. First and foremost, suction power is crucial. A vacuum system with high suction power can effectively remove debris and contaminants from various surfaces, ensuring a clean and safe working environment. This not only improves operational efficiency but also prolongs the life of machinery by reducing wear and tear caused by dust and other particles.

Another critical feature to consider is the filtration system. Advanced filtration technologies, such as HEPA filters, can capture even the smallest particulates, ensuring that the air quality remains high in the workspace. Efficient filtration minimizes the risk of cross-contamination, particularly in industries such as food processing and pharmaceuticals. Additionally, ease of maintenance plays a significant role. Equipment designed for easy access to components allows for quicker servicing, reducing downtime and maintaining continuous operational flow. Identifying these features can significantly aid in the selection of vacuum systems that truly enhance industrial efficiency.

Real-World Case Studies: Vacuum Equipment Boosting Factory Output

In today’s competitive industrial landscape, vacuum equipment has emerged as a critical component in optimizing factory output. A recent report from the International Society for Automation (ISA) highlights that industries employing advanced vacuum systems have seen a productivity increase of up to 25%. This is largely attributed to the enhanced material handling capabilities and the improved processing efficiency these systems bring, allowing manufacturers to maintain streamlined operations with minimal downtime.

For instance, in the automotive sector, the implementation of high-performance vacuum equipment led to a notable enhancement in assembly line efficiency. A leading manufacturer reported a 30% reduction in cycle times after integrating vacuum lifters into their production process. Additionally, a study by the Vacuum Technology Association (VTA) revealed that factories using vacuum technology experienced a 15% decrease in product defects due to more precise handling and assembly methods. These real-world case studies underscore the transformative impact of vacuum equipment on industrial processes, proving that investing in quality vacuum solutions is not merely a matter of operational improvement, but a strategic move towards greater competitiveness in the market.

Exploring the Impact of Vacuum Equipment on Industrial Efficiency

This bar chart illustrates the percentage increase in factory output achieved by implementing advanced vacuum equipment across different manufacturing facilities. The data shows a significant boost in efficiency, highlighting the benefits of utilizing vacuum technology in industrial processes.

Future Trends in Vacuum Technology for Industrial Applications

As industries continue to evolve, vacuum technology is becoming increasingly integral to maximizing efficiency and productivity. Forecasts indicate that the market for vacuum equipment will see significant growth, particularly in sectors such as semiconductor manufacturing, where the use of porous ceramic vacuum systems is projected to expand from $224.51 million in 2024 to $326.89 million by 2032. This surge underscores the pivotal role that advanced vacuum systems will play in supporting complex industrial processes.

Moreover, the integration of digital technologies is set to revolutionize manufacturing environments. For instance, insights from recent industry analyses highlight that quality flow controllers (MFCs) are gaining traction in emerging economies, with nations like Thailand, India, and Malaysia poised for substantial market expansion. Such developments indicate a robust demand for sophisticated vacuum and control equipment, which will likely enhance automation and operational intelligence across various manufacturing sectors. As the industry adapts to these technological advancements, the focus on smart manufacturing practices is expected to intensify, driving further innovation in vacuum technology applications.